English page

- HOME

- English page

Product info

Company summary

- Class1 medical devices marketing licensee

- Medical device manufacturing

- ISO 13485 certified factory

Main fields

- Medical device design & manufacturing

- Precision machining,etc.

- Assembly,inspection,packaging,blast treatment,etc.

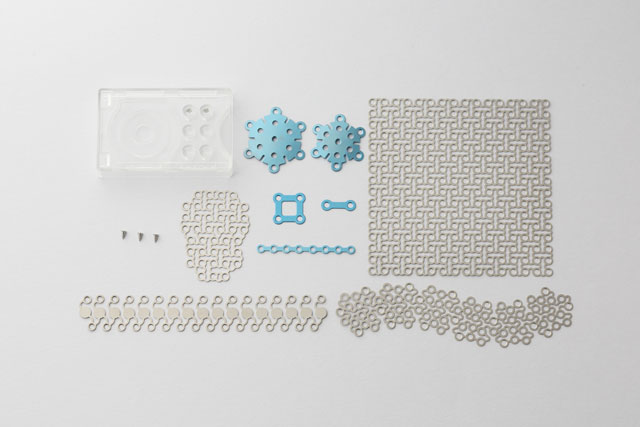

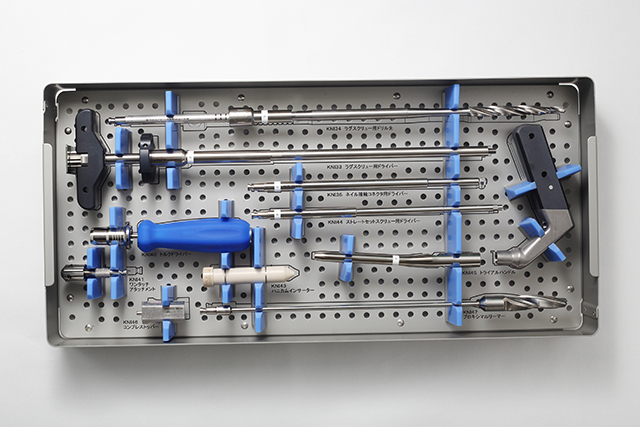

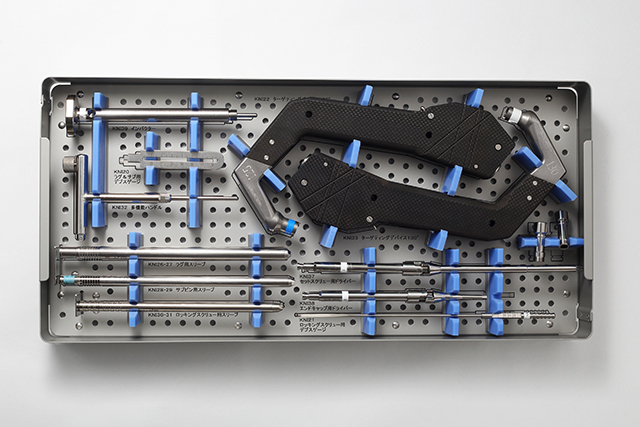

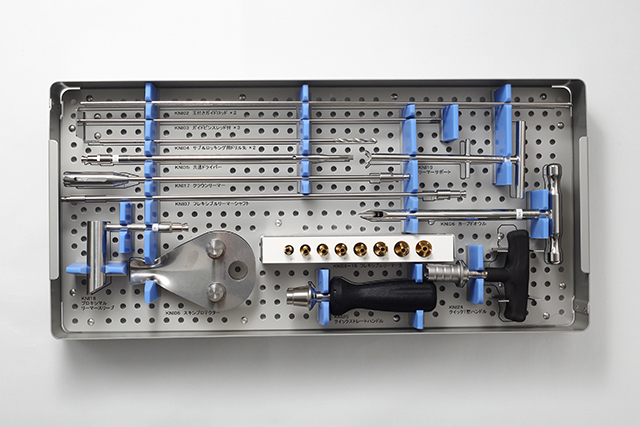

Main products

- Dental implants

- Orthopedic implants

- Neurosurgery implants

| Company Name | PROSPER Co.,Ltd. |

|---|---|

| Representative | Representative Director Masanori Mizukami |

| Address | 〒945-1355 2028-6,Karuigawa Kashiwazaki-City,Niigata Prefecture Postal Code: 945-1355 |

| TEL | 0257-24-5277 |

| FAX | 0257-24-8620 |

| URL | https://www.pros-per.co.jp |

| info@pros-per.co.jp | |

| Line of Business | Design & production and build-to-order manufacturing of medical devices. |

| Capital | 20,000,000yen |

| Date Established | May 8,1992 |

Map

Directions:10 minutes by car from the Kashiwazaki I.C.on the Hokuriku Expressway

ISO 13485 Certified Factory

Our factory is certified with ISO 13485 certification,a system for stably guaranteeing the quality of medical devices.

Business Introduction

PROSPER Co.,Ltd.(PRS)was founded in 1992,and began manufacturing medical devices in 1997.We are involved in the design and manufacture of medical devices, and build-to-order production.

We are working for success in a variety of fields,starting with the processing of metals like titanium and stainless steel,plastic processing,assembly,sterilization,packaging,and more.

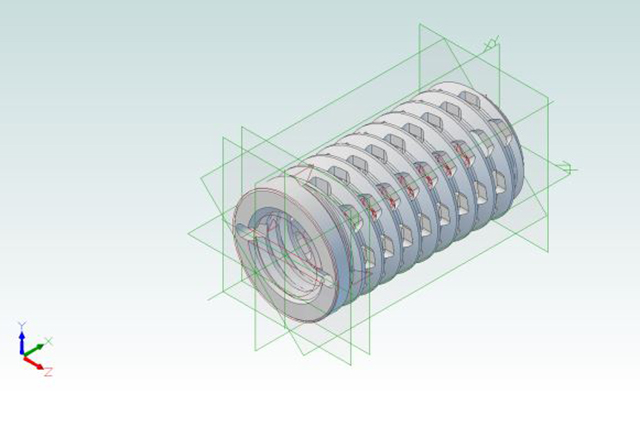

NC lathe machining

- Titanium processing

- Stainless steel processing

- Plastic processing

We manufacture medical devices through machining.

Design & manufacturing/build-to-order production

We place the highest importance on technical quality and aftercare to make products that meet our customer’s ideas and desires.

Surface Treatment Processing

- Barrel polishing

Product,polishing stone and compound are put into barrel machine,and processed. - Buffing

The surface of the product is given a glossy sheen. - Blast treatment

Product’s surface is blasted.

Test inspection,assembly under sterile conditions,decorative packaging

- Autoclave treatment

High Pressure steam sterilization is carried out at 121℃. - Cleanroom

Assembly,drying,and primary packaging are carried out in the cleanroom. - Decorative packaging

We place the product and manual,etc.into a decorative box and carry out fainal packaging.

Autoclave,cleanroom

Equipment introduction

Our company is fully equipped with all process.

Process management

Medical equipment and general products / parts

STEP.1

Design

STEP.2

NC lathe machining

STEP.3

Assembly

STEP.4

Sterilization

STEP.5

Packaging of medical devices/finished products